Offshore drilling, well, and engineering services provider Odfjell Technology said Wednesday it had achieved "an industry-first" for cleaning blowout preventers (BOPs), reaching a 50% time reduction during a trial.

Over a test period of six months, Odfjell Technology revised the procedure for cleaning the BOP on the Johan Sverdrup platform offshore Norway by increasing the pump rate to allow more water flow into the BOP cavities to aid debris removal, the company said.

The annular and variable rams were flushed with two passes at the new recommended flow rates to remove debris, then the BOP stack was flushed at the same rate using Odfjell Technology’s RizeRdillo Advanced Jetting Tool. The flow rates went from 1500 litres per minute (LPM) to 5500LPM while flushing the annular and from 3000LPM to 5500LPM while flushing the BOP, Odfjell Technology said.

According to Odfjell Technology, Results from the successful test period proved that no damage occurred to the BOP and annular with the recommended pump rates, and between six and 12 hours of time could be saved using this new procedure.

"The RizeRdillo Advanced Jetting Tool allows for higher pump flow rates, enabling a larger volume of fluid with less pump pressure. This maximizes riser cleaning efficiency to reduce operating costs and non-productive time," the company said.

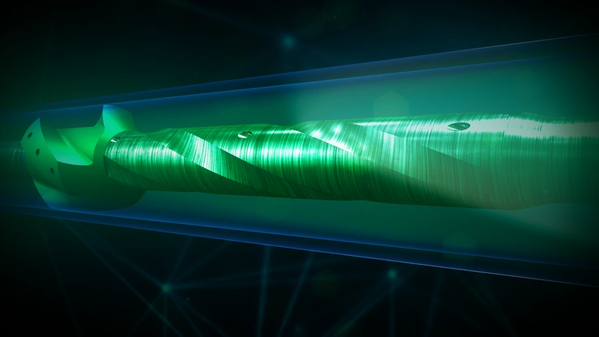

Johan Sverdrup - Credit: Odfjell Technology

Johan Sverdrup - Credit: Odfjell Technology