An Australian engineering house is partnering with a UK technology organisation to test a prototype system that could enable longer distance subsea tiebacks to be built.

Worley’s INTECSEA consultancy is working with the UK's Oil & Gas Technology Centre (OGTC) on the project, which would see prototype testing of its Pseudo Dry Gas (PDG) liquid removal system. By reducing back pressure in the pipeline, the technology would eliminate the need for topsides and costly compression, reducing the associated high carbon emissions. This allows for much greater tie-back distances.

The next step will be to find an operator willing to undertake a pilot project of an integrated unit. An ideal pilot would be maintaining gas production from an existing tieback post water breakthrough in a mono ethylene glycol (MEG) constrained environment, says Worley. "This would create a significant value impact, with a minimal downside. Given the range of applications for this technology across a broad spectrum and the positive underlying economics, the project team is hopeful an operator will step forward," says the firm.

The prototype testing is based on a recently completed techno-economic concept study, which was also funded through the OGTC. The study demonstrated the system’s high recovery levels, providing an additional US$10 billion in revenue over the alternatives, according to Worley. This would result in the strongest economic performance for a known stranded gas basin; north of the Shetland Islands. The study also demonstrated that upstream CO2 emissions were reduced by 65-80% using this technology, significantly reducing the environmental footprint.

An additional application for PDG that was studied as part of the original OGTC scope was gas disposal for small oil pool developments. This also provides a stand-alone economic case with significant follow through benefits for ‘normally unmanned’ facilities, due to the removal of high maintenance topside gas processing equipment, says Worley.

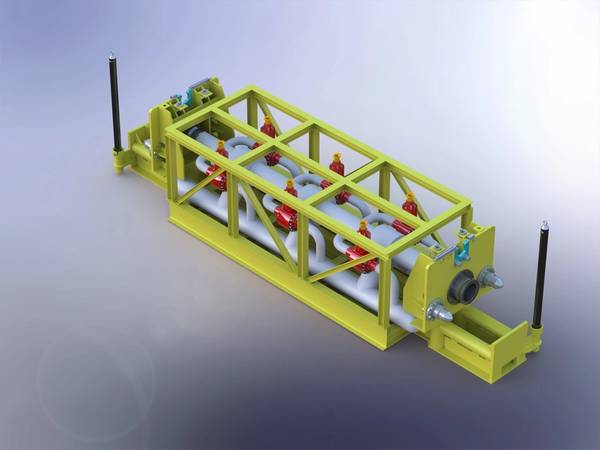

The results of both studies have driven further technology development and wider industry support, including a six-inch scaled prototype of the liquid removal unit, which will be tested over a six-month period at Cranfield University’s flow loop facilities in the UK. This unit will simulate the expected flow conditions typically found within a gas / gas condensate subsea tie back system to demonstrate the liquid removal efficiencies and hence provide confidence in the macro flow assurance.

Lee Thomas, INTECSEA’s Engineering Lead for PDG technology, anticipates that the prototype testing will raise the technology readiness level to the point where a pilot project can be considered viable via a programme of enhanced factory acceptance testing for an integrated unit.

Commenting on the project, he said: “The solution is elegantly simple; it uses multiple passive liquid removal units and a liquid disposal pipeline connected to proven standardized pumps. I am delighted that the OGTC’s funding will allow us to move from computer-based simulations, through to physical testing, with a diverse range of Operators and Tier 1 contractors, demonstrating industry collaboration at its best.”

Graeme Rogerson, Marginal Developments Project Manager for the OGTC, added: "There are over 360 marginal developments in the UK Continental Shelf, with approximately 3-50 million barrels of untapped oil and gas. Technology development is key to unlocking this potential and why we are excited to support Worley’s INTECSEA in developing its Pseudo Dry Gas system, improving reserves recovery while reducing the industry’s carbon footprint.”