The offshore industry is going through an unprecedented digital disruption that transcends asset classes and is creating a roadmap to safer and more cost-effective operations.

The current face of that transition is the ‘digital twin’, a virtual replica of physical assets, processes and systems that ultimately will be used by owners to predict failures before they happen and make production more reliable.

The technologies that enable advanced data analytics – such as artificial intelligence, machine learning, streaming analytics and parallel processing power – have matured to the point that huge volumes of data now can be cleaned and analyzed in near real-time, rather than days. The offshore industry has always produced a lot of data; simply put, processing it has become a far more time- and cost-effective process.

Ongoing pilot projects – with rig and platform builders and operators, offshore supply companies and the floating production, storage and offloading unit (FPSO) community – are currently performing the type of real-time data analyses that improve asset reliability, safety, drilling efficiency and well production. They are proving that asset downtime can be reliably reduced.

It’s a common joke among data specialists working in the offshore sector that you can ask 10 people in a room to describe a digital twin and you will get 20 definitions. That may be because the elements that make up a digital twin are bespoke to why it is being built – i.e., the purpose for which the asset owner is building it.

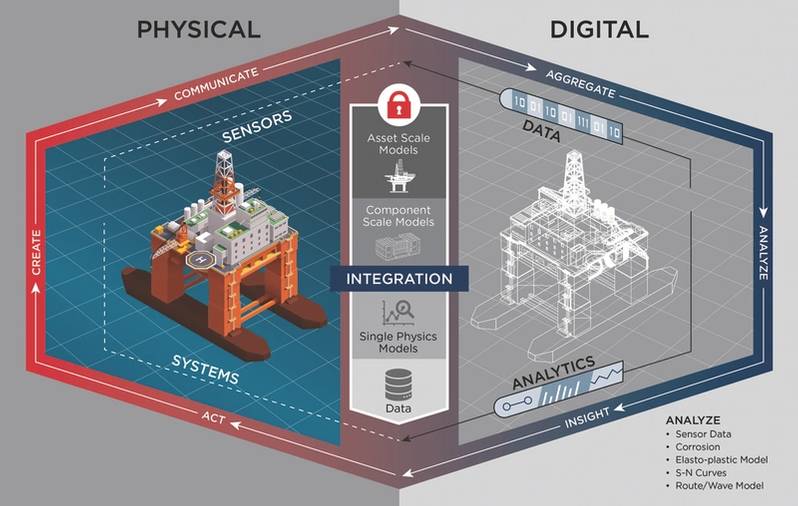

At its heart, a digital twin is a virtual condition model of an asset on which simulations can be run to improve/predict operational characteristics without having to physically affect the asset.

The virtual asset’s scale – whether it represents a simple component or complex marine ecosystem – detail (will every bracket on the rig be modeled and its condition tracked?) and the frequency at which it is to be updated determines the complexity of the model.

Once the scale is decided, the owner then defines the analytical capabilities of the condition model; will operational decision-making be improved by real-time data-based analytics, predictive analytics, physics-based analytics, finite element analysis, etc.

To some degree, classification societies have been working with their clients on basic digital twins for some time. But rapid recent advances in computational power have allowed the scope of those models to be aggressively expanded.

Progressive owners now have the power to expand the scope of the assets they choose to model from equipment and subsystems to an entire rig, platform or floating production system and their wider ecosystems.

This is a significant step forward. Why? Because an asset’s performance is less determined by how well its pumps or top-drives working in silo than by how the equipment and components collectively perform within their environment, and how that impacts overall operations.

As the technologies advance, the scope of digital twins is taking on the shape of the entire ecosystem, including the human element; it is now possible to calculate models to determine what the impact of the performance of a component will be on the people operating on a rig, FPSO or platform.

(Image: ABS)

(Image: ABS)

When that becomes a reality, owners will be able to virtually represent what will happen to the performance of their assets in various operating environments. Adjusting the performance of complex assets in real time requires engineering, physics and machine-learning elements to be fully instrumented, and the data-processing power to support live analyses. Now that is possible.

Most of the findings from the offshore pilots currently exploring the industry applications for digital twins have yet to be released. But first-mover marine applications are already showing great promise.

ABS recently released the preliminary findings from a project with Military Sealift Command (MSC), a division of the U.S. Navy, in which MSC implemented digital-twin technology to improve operational readiness, optimize maintenance and minimize unplanned failures for the ships involved in the pilot.

Class societies such as ABS have been building the capabilities to help their clients capitalize on the digital revolution – including the opportunities that arise from disruption – for some time. On the human level, the traditional class workforce of engineers and naval architects has gradually been blended with systems engineers, cyber engineers, risk engineers, data analysts and data scientists.

As the current projects suggest, class now has the capability to ingest unprecedented amounts of raw structured and unstructured data – improving the data quality as it comes in – to undertake not only performance analyses, but also the anomaly detection that is at the heart of predictive analytics.

ABS is now transforming this experience into models that can be dropped onto a digital twin of any scale and ultimately help offshore owners to improve the performance of their assets by better predicting and mitigating potential safety issues.

Condition-based monitoring is a prerequisite to condition-based maintenance. Aside from fulfilling a mandate to provide independent technical advice to asset owners in the offshore industry, a transition to condition-based maintenance will simultaneously reduce the intrusiveness of class by uncoupling its requirements from rigid calendar-based regimes.