In June, independent global completions service company Tendeka announced it had secured the world’s largest sand and inflow control contract for the Troll field on the Norwegian continental shelf (NCS).

The four-year contract with Equinor will see the Aberdeen-headquartered company deliver and install up to 100,000 meters annually of its sand screens and FloSure Autonomous Inflow Control Devices (AICD) for sand-face completion. The agreement also offers an additional five two-year extension periods.

The two companies have worked together for seven years with Tendeka providing screens and ICD/AICDs for the Troll field as well as other Equinor licenses.

Since Tendeka first deployed FloSure technology in the Troll field in 2013, the field adjustable production optimization technology has been enhanced for use in new and retrofit applications across five continents from marginal heavy oil developments in Canada to new field developments across Asia and gas cap expansions in the mature North Sea basin.

Offshore Engineer spoke with Karianne Amundsen, Scandinavia Area Manager with Tendeka, to find out more.

Tendeka has a history with Equinor and the Troll field. How has the company been supporting the operator?

It’s been a great pleasure and experience to work alongside Equinor on this field which represents the backbone of Norwegian oil and gas production. We have learned a lot and really look forward to continuing the collaboration on optimizing production.

Tendeka has secured the world’s largest sand and inflow control contract for the Troll field on the Norwegian continental shelf

Tendeka has secured the world’s largest sand and inflow control contract for the Troll field on the Norwegian continental shelf

(Photo:- Harald Petterson, Equinor)

As a large subsea development, which started oil production in 1995, Troll’s multilateral, horizontal wells are drilled with total reservoir length, between 3 to 5 kilometers within the thin oil column. [1] The FloSure AICD is incorporated with premium sand screens to provide sand and inflow control for the thin layer oil rim which is overlaid by a large gas cap. The aim is to maximize oil production using our FloSure AICDs to ensure contribution from all reservoir sections and limit gas production by postponing gas breakthrough and choking gas production after gas breakthrough. Currently, more than 50 wells are equipped with AICDs, demonstrating significant increase in cumulative oil production.

How has continued collaborative technology development between Tendeka and Equinor been key to the continued success of this project?

Tendeka has a strong commitment to continuous technology development. Throughout the last few years and prior to the contract award, Tendeka worked closely with Norwegian operators to further develop and qualify the FloSure rate-controlled production AICD, delivering improvements in overall performance and gas control.

As a company, we have grown significantly since our work began on Troll and while it remains a large project for the company, so far, we have installed more than 35,000 FloSure AICD valves in over 210 wells worldwide. This demonstrates a significant increase in cumulative oil production and project profitability for our customers.

It’s an incredibly versatile technology. Knowing how to apply the technology correctly by quantifying the value and optimizing the design is crucial. Based on extensive multiphase testing, we’ve developed our own modelling software to be able to predict the performance of the AICDs in any application. This is where our expertise is second to none.

It is a testament to the hard work of the team, commitment to continuous improvement and a significant investment in production optimization technology that we have secured this new framework agreement for the next four years.

How have sand-faced completions had to adapt in recent years to meet the challenges and requirements of smarter and longer horizontal multilateral wells?

Traditionally, the oil and gas industry drilled and developed short, vertical wells which required minimal and less complex sand-faced completion equipment.

Many wells today are long horizontal wells which often need inflow control devices to manage the inflow. Integrating different types of sand and inflow control within flexible solutions will be important going forward. On Troll for example, all new wells are infill wells that are drilled in between branches of older or abandoned wells, these intersect areas of varying oil column thickness. Here, wells need to be drilled with care to avoid early gas breakthrough and sand production to surface.

The depth of the oil/water contact in these longer, horizontal multilateral wells varies, as does the reservoir properties. Therefore, the wells are completed with an integrated sand and inflow control module that are replacing traditional standalone sand screens. Integrated sand and inflow control will also be compatible with smart branch control using Interval Control Valves to monitor flowing and shut-in pressure for the individual branches.

AICD technology is fundamental for continuing oil production on profitable margins and as such, significant mechanical design modifications have been implemented for improved completion integration, robustness and longevity in sanding environments

Preventing early gas breakthrough into production wells can clearly increase total oil recovery and reduce gas and/or water production. How is this achieved?

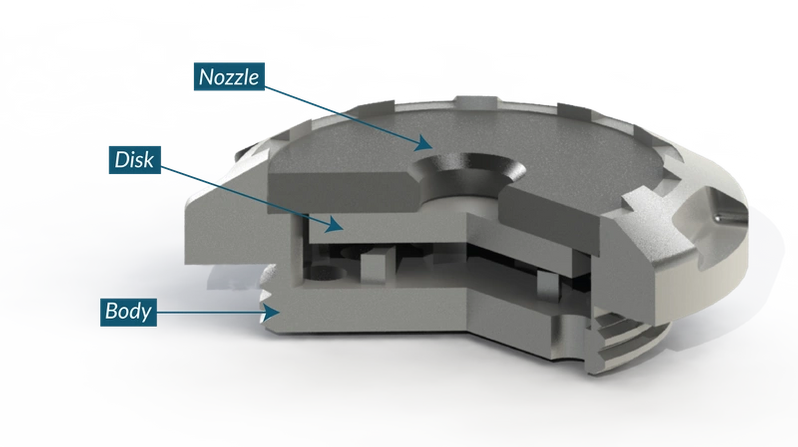

The AICDs comprise of only three components: valve body, nozzle and disc and are small enough to be installed within standard passive ICD housings. Importantly, the size of the nozzle on the device is interchangeable at the rig based on drilling results.

AICD construction (Image: Tendeka)

Deployed as part of the lower completion using zonal isolation packers to divide the reservoir into compartments, the AICD can be integrated with sand control screens for soft formations.

The device can be threaded directly into the base pipe and the valve can be mounted or replaced at any time. Each screen joint may have up to four threaded ports compatible with the AICD.

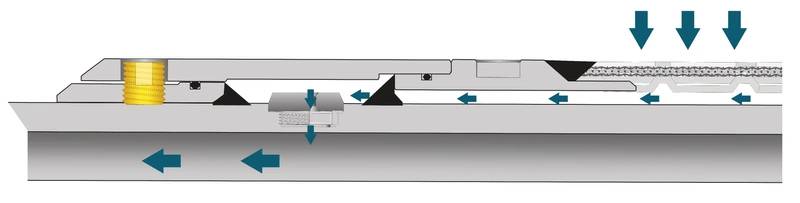

The reservoir fluids enter the completion through the sand screen filter and flow into the inflow control housing where the AICD is mounted. The fluids then travel through the AICD into the production stream to the surface together with the production from the rest of the screens.

Autonomous ICD flow path (Image: Tendeka)

Autonomous ICD flow path (Image: Tendeka)

When gas or water flows through the AICD valve at the same drawdown, the velocity of the water and gas will increase, reducing the dynamic pressure. To restrict the flow rate of low viscosity fluids, this action will levitate the disk toward the inlet to choke the flow.

Aside from Troll, AICDs has been used across more than 120 wells globally with varying reservoir properties and production issues. How does it compare with conventional ICD technology?

FloSure AICDs have been deployed successfully in light, medium and heavy oil wells to overcome water or gas breakthrough and ensure uniform production longevity.

For example, it has also been successfully implemented as a pilot project in horizontal wells at the Jasmine and Ban Yen fields, in the Gulf of Thailand to reduce gas breakthrough. The AICD well has now been producing for more than one year and at significantly lower gas to oil ratios than previously. [2]

In Canada, the design resulted in an overall increase in oil production by 150-250% with water production reduced by 40-50%. This led to an improved return on investment of more than 250% per well, with a far lower risk of water problems compared to the previous solutions applied. [3]

Several wells have recently been completed with AICDs for a major operator in the Middle East. The AICD completion has reduced the water cut of the wells to below 50% for AICD wells compared to 90% in the analogue wells, limiting the water production from the fractures. Several other new AICD wells are being planned in the Middle East.

Following successful installation in pilot wells, retrofitting existing completions with AICDs is now a common practice for some operators.

What wider benefits can this bring for global operators?

Tendeka has so far employed more than 35,000 FloSure AICD valves in over 210 wells worldwide. The implementation of AICDs has not added complexity or HSE risks to the completion and production of these wells.

In fact, as a proactive-reactive device, AICD completion was found to be the most efficient completion at controlling the gas and water production from high productive zones or fractures, compared to the wells equipped with ICDs and other conventional completions.

Its application provides operators with significant long-term benefits as well as a type of insurance policy against geological and dynamic reservoir uncertainties to reduce the risk and variation in the expected oil production profiles.

This clearly demonstrates that implementing AICDs can significantly increase oil production, extend well life, and ultimately lead to greater oil recovery in a wide range of environments and applications.

References

1.M. Halvorsen, M. Madsen, M. Vikoren Mo, Equinor and I. Mohd Ismail and A. Green, Tendeka (2016) Enhanced oil recovery on Troll by implementing autonomous inflow control device. SPE Bergen One Day Seminar, Bergen Norwasy, 20 April 2016, SPE-180037-MS

2.M. Triandi, I. Chigbo, T Khunmek, Mubadala Petroleum and I Mohd Ismail, Tendeka (2018) Field case: Use of autonomous inflow control devices to increase oil production in a thin oil rim reservoir in the Gulf of Thailand. ADIPEC, 12-15 November, 2018. SPE-193305-MS

3.M. Moradi, M. Konopczynski, I. Mohd Ismail and I. Oguke, Tendeka (2018) Production optimisation of heavy oil wells using autonomous inflow control devices. SPE International Heavy Oil Conference & Exhibition, 10-12 December, Kuwait City, Kuwait. SPE-193718-MS