Hydrogen embrittlement was found to have caused a 2020 flowline jumper failure in the U.S. Gulf of Mexico, the Bureau of Safety and Environmental Enforcement (BSEE) said in a recent report.

The incident, which occurred on July 24, 2020, in the Fieldwood Energy-operated deepwater Katmai field, resulted in the release of approximately 479 barrels of oil. The affected well, Well #1, is located in about 2,082 feet of water on Green Canyon Area Block 40, approximately 140 miles south of New Orleans. The K1 Jumper is approximately 26 miles from the Tarantula platform host facility in South Timbalier area, Block 308, and is connected to the host facility by the Katmai flowline.

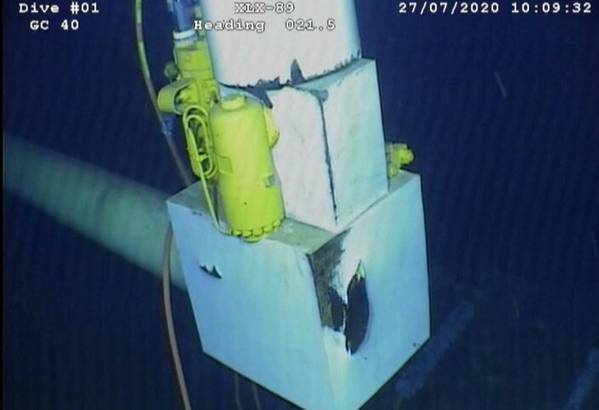

A panel consisting of BSEE subject matter experts, engineers, inspectors and specialized investigators conducted its investigation to determine the probable causes and contributing factors that led to the leak resulting from a flowline jumper failure and fracture of four of the eight flange fasteners at a flanged connection.

According to BSEE's panel investigation report, the fractured studs were composed of a corrosion-resistant nickel-based alloy, which are susceptible to hydrogen embrittlement in subsea environments. Hydrogen embrittlement, also referred to as hydrogen stress cracking, occurs when metals absorb hydrogen, leading to reduced ductility and loadbearing capacity.

BSEE also found, among other contributing factors, that a gap in the quality assurance/quality control process allowed for a non-compliance subsea flange faster installation.

As a result of its investigation, BSEE issued a safety alert that includes recommendations that operators and contractors utilize an industry-knowledgeable metallurgist to evaluate all current and future subsea fasteners to verify fasteners are fit for service and not prone to hydrogen embrittlement or any other environmental cracking failures, share subsea leak detection system learnings with industry, and emphasize that company, contract and sub-contract personnel enact management of change when there are modifications associated with equipment, operating procedures, personnel changes, materials and operating conditions.