A range of cutting-edge technologies, including specialized drilling equipment, custom subsea systems and purpose built floating production storage and offloading (FPSO) units, help Brazilian national operator Petrobras and its partners tackle the complex challenges associated with the development of ultra-deepwater pre-salt plays.

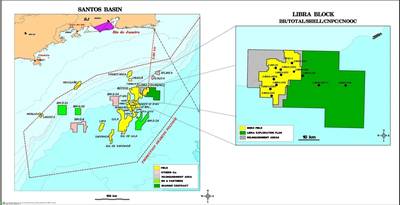

On October 2, the consortium developing the Mero field concluded the first extended well test (EWT) at the large pre-salt play with the Pioneiro de Libra FPSO, jointly owned by Teekay Offshore and Brazil’s Ocyan. The ultra-deepwater Mero field, formerly known as Libra Northwest, is located in the northwestern sector of the giant Libra block, which is about 180 kilometers south of Rio de Janeiro, within the Santos Basin. First oil was produced in November last year. The Mero field holds approximately 3.3 billion boe in high-quality - 29º API - carbonate reservoirs. The single-well test reached a record-breaking flow rate of nearly 58,000 boe per day at its peak, an impressive result in ultra-deep waters. Now Petrobras is in the process of hooking up another gas injection well to the FPSO that will be closer to the oil-producing well in order to start a new extended well test on the same location to analyze the speed at which gas breakthrough will happen.

The technologies applied during the EWT were fundamental to obtaining high-quality data and reducing uncertainties about the reservoir, which is expected to allow the accelerated deployment of the four final production systems at Mero in the coming years. Each system will be capable of producing up to 180,000 barrels of oil per day. In addition, these technologies will contribute to safer and more efficient development of upcoming projects in Brazil.

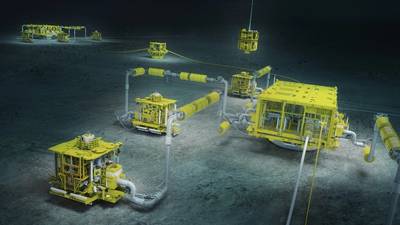

Recently, Aker Solutions signed a contract with Petrobras to provide an integrated subsea production system and related services for the Mero 1 project within the Mero field development. The subsea production system will consist of 12 vertical subsea trees custom designed for Brazil’s pre-salt, four subsea distribution units (SDU), three topside master control stations for the Mero 1's Guanabara FPSO and a host of spare parts. An SDU is a distribution center for the umbilicals to several trees, and was designed to handle the specific characteristics of the hydrocarbons present in the reservoir. The order also includes installation and commissioning support services. Aker Solutions’ sprawling manufacturing facility in São José dos Pinhais, in the state of Paraná, and its subsea services base in Rio das Ostras in Rio de Janeiro have already started the work. Deliveries are scheduled for 2020, with installations scheduled between 2020 and 2023.

Example of an Aker Solutions subsea production system (Image: Aker Solutions)

The subsea production system will be hooked up to the first full-scale FPSO for Mero, known as the Guanabara FPSO. The FPSO is scheduled to come on stream in 2021 and will have capacity to process up to 180,000 barrels of oil per day and 12 million cubic meters of gas per day. Ten appraisal wells were drilled in the Mero field area in order to determine the commercial viability of the field, while two more are planned to be drilled in 2018. The wells discovered oil columns as thick as 410 meters. The high flow rates and pressures, the significant presence of gas associated to oil, in addition to the high content of CO2 in the area have demanded the development of latest-generation solutions to facilitate production. As such, Petrobras and its partners have developed new technologies designed to operate in these environments, with water depths ranging from 1,700 to 2,400 meters, and total depths that reach 6,000 meters.

One of the pioneering solutions included the installation of the first FPSO dedicated exclusively to EWTs. This innovation, which is capable of re-injecting the gas produced, brings better results to the consortium and the environment, because it allows the elimination of continuous burning of gas, thus minimizing CO2 emissions into the atmosphere and enabling the production of wells at their maximum potential. To produce during EWT without restrictions made the acquisition of dynamic data from the reservoir more efficient and thorough. In the deployment of the EWT, the first pre-launch of flexible lines with floats in ultra-deep waters was carried out. This method anticipated the start of well production by 43 days, compared to a scenario without the pre-release of the lines.

Petrobras is the operator of the consortium developing the Libra area with a stake of 40 percent. Other partners include Shell (20 percent), Total (20 percent), CNPC (10 percent) and CNOOC (10 percent). The production sharing contract is managed by Pre-Sal Petróleo S.A (PPSA).

(Image: Petrobras)