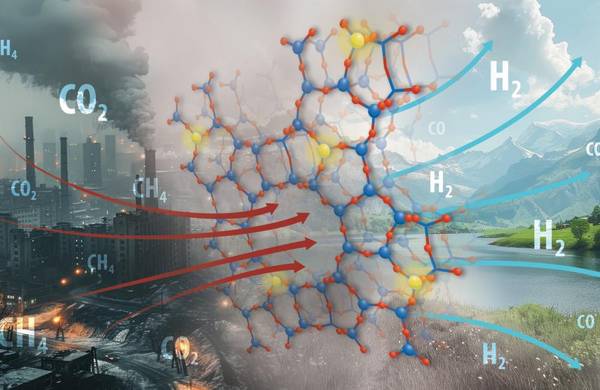

A chemical reaction can convert methane and CO2 into valuable building blocks for cleaner fuels and feedstocks, but the high temperature required for the reaction also deactivates the catalyst. A team led by the Department of Energy’s Oak Ridge National Laboratory (ORNL) has found a way to thwart deactivation.

The team improved a reaction called dry reforming of methane that converts methane and CO2 into syngas, a valued mixture of hydrogen and carbon monoxide used by oil and chemical companies worldwide.

In countries lacking oil reserves, syngas derived from coal or natural gas is critical for making diesel and gasoline fuels. Moreover, syngas components can be used to make other commodity chemicals. Hydrogen, for example, can be used as a clean fuel or as a feedstock for ammonia to create fertilizer.

Methanol, an alcohol that can be made from syngas, is a source of ingredients for producing plastics, synthetic fabrics and pharmaceuticals. Methanol is also a good carrier of hydrogen, which is hard to pressurize and dangerous to transport. As the simplest alcohol, methanol contains the highest ratio of hydrogen to carbon; it can be safely transported and converted to hydrogen at the destination.

Today, most commercial syngas is made by steam reforming of methane, a process that requires large amounts of water and heat and that also produces CO2. By contrast, dry reforming of methane requires no water and actually consumes CO2 and methane.

To attain significant conversion of reactants, the reforming reaction must be conducted at temperatures greater than 650 degrees Celsius, or 1,200 degrees Fahrenheit. At this high temperature, the catalysts undergo two deactivation processes. One is sintering, in which you lose surface sites that undertake the reaction. The other is the formation of coke — basically solid carbon that blocks the catalyst from contacting the reactants. Likewise, coking chokes a catalyst.

By tuning interactions between the metal active sites and the support during catalyst synthesis, the scientists suppressed coke formation and metal sintering. They developed a new catalyst that provides outstanding performance for dry reforming of methane with extremely slow deactivation. It consists of a crystalline material called a zeolite that contains silicon, aluminum, oxygen and nickel. The zeolite’s supportive framework stabilizes the metal active sites.

“Zeolite is like sand in composition,” ORNL’s Junyan Zhang said. “But unlike sand, it has a sponge-like structure filled with tiny pores, each around 0.6 nanometers in diameter. If you could completely open a zeolite to expose the surface area, 1 gram of sample would contain an area around 500 square meters, which is a tremendous amount of exposed surface.”

To synthesize the zeolite catalyst, the researchers removed some atoms of aluminum and replace them with nickel.

Next, the researchers will develop other catalyst formulations for the dry reforming of methane reaction that are stable under a broad range of conditions.