Dutch offshore crane construction firm Huisman has confirmed it has received an order to deliver what it says will be the largest leg encircling crane for Van Oord's new offshore installation vessel designed to install huge wind turbines of up to 20MW.

"This crane will be the largest Leg Encircling Crane that Huisman has developed to date in terms of lifting capacity, boom length, installed power, and technical features," Huisman said.

"Its lightweight, yet robust design, high level of reliability and limited tail swing makes the LEC highly suitable for the construction of offshore wind farms. Thanks to its fully electrically driven system, the crane has a low energy consumption and thus contributes to the reduced CO2 footprint of Van Oord’s new offshore installation vessel," Huisman said.

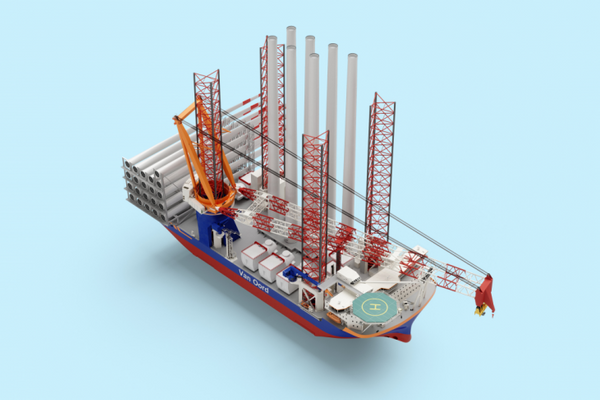

As previously reported, last month ordered the giant jack-up unit, able to operate on methanol, from Yantai CIMC Raffles Shipyard in China. The ship is expected to enter the market in 2024

The 175-meter offshore installation vessel will be able to transport and install both foundations and turbines at offshore wind farms. It will be equipped with a Huisman crane able to lift more than 3,000 tonnes.

Commenting on the vessel and the crane order, Pieter van Oord, CEO of Van Oord said: “This investment prepares us for the increase in scale in the offshore wind industry and allows us to maintain our leadership position. The crane to be delivered by Huisman will support us to achieve that target.”

David Roodenburg, CEO of Huisman: “We are very proud of this order from Van Oord, who has been a frontrunner in the offshore wind industry since 2002. We fully support their ambition to make offshore wind a more competitive energy source and are grateful for their trust in us to build our largest LEC to date. With this contract, we can build on the success of the 1,600mt LEC for the Aeolus and once again show our commitment to work on continuous product improvement and new technical solutions.”

The scope of work for Huisman consists of the design, engineering and construction of the crane at its production facility in Zhangzhou, China. The crane will be delivered and integrated in cooperation with the vessel’s designer Knud E Hansen at Yantai CIMC Raffles Shipyard in China, scheduled for 2023.

Below are the crane specs, as shared by Huisman: