The Dutch oil and gas company ONE-Dyas is the first to purchase a Liebherr offshore crane, type RL 2600, in combination with the recently launched service concept Liebherr Intelligent Maintenance (LiMain).

LiMain is a fully digital, remote, and semi-automatic maintenance system, and with it ONE-Dyas can remotely maintain the new Liebherr crane

on the unmanned platform.

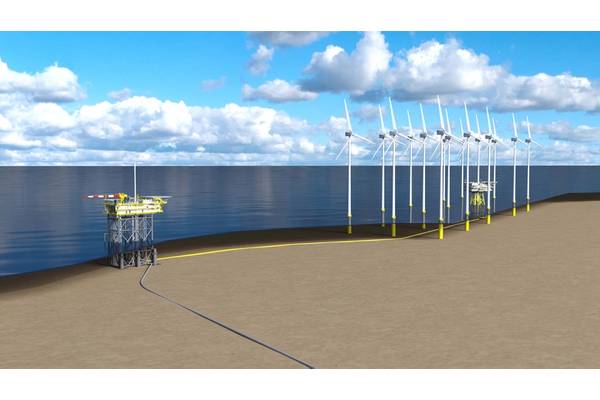

ONE-Dyas will install the first electrified gas production platform in the North Sea, designed to run entirely on offshore wind power from the nearby Riffgat Offshore Wind Farm. The N05-A project is part of the so-called GEMS area, an area approximately 20 to 80 km north of the Ems estuary.

“We have made a strategic decision to purchase the RL 2600 in combination with LiMain’s innovative remote maintenance concept," said Michel Mens, Lead Engineer E/I and Rotating Equipment at ONE-Dyas. "Our aim is to minimize the maintenance effort significantly, but at the same time to ensure a service life of the crane of more than 20 years.

With LiMain, maintenance can be carried out remotely, from the shore, saving signficantly the time, money and emissions spent delivering maintenance crews to the rig.

With LiMain maintenance independent of time and place is possible. Platform operators can choose from various modules and so determine the

With LiMain maintenance independent of time and place is possible. Platform operators can choose from various modules and so determine the

degree of autonomy and scope of intelligent maintenance for the crane. Image courtesy Liebherr