Dutch company Barge Master has developed a motion-compensated feeder solution for the next generation of offshore wind turbines, called BM-Feeder.

The company said that its motion-compensated platform with its adjustable payload capacity is capable of "feedering" all turbine components, including future generations of wind turbine generators.

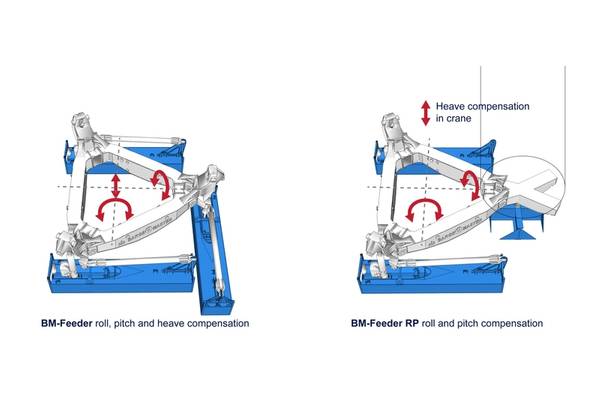

"The BM-Feeder can be placed on an offshore vessel or barge and ensures that the components are kept completely stable for hook on and lift-off by the Installation Jack-Up. Motion-compensated feedering offers major benefits for the feeder operation. It enables a controlled hook on and lift off by the crane of the Installation Jack-Up," Barge Master said.

"After lift-off, it decreases the risk of re-impact, by eliminating the swing and heave motion of the components. The BM-Feeder can operate in sea states of up to Hs 2.5 meters and thereby significantly increases the workability of the operation," Barge Master explained.

The new BM-Feeder platform is based on our existing BM-T700 systems. According to the company, the BM-Feeder can be mobilized on a U.S. flagged vessel or sea-going barge, able to load the components in a U.S. port and sail out to the installation Jack-up, "making it a fully Jones Act compliant solution."

Photo: The BM-Feeder with tower seafastening and a tower section.

Photo: The BM-Feeder with tower seafastening and a tower section.