Offshore drilling services provider Ensco has rolled out a new proprietary solution engineered to provide greater pipe tripping safety and efficiency.

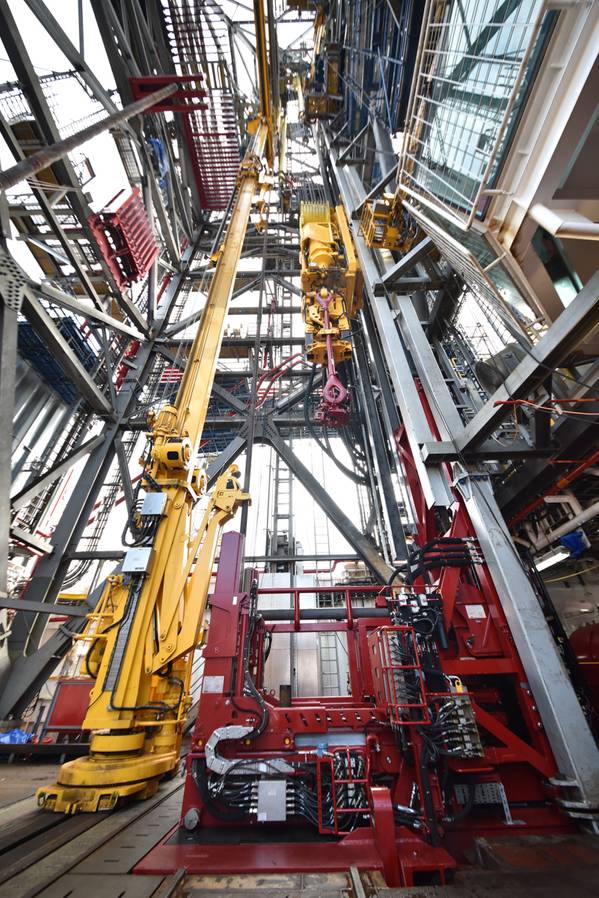

When used in concert with other key equipment, sensors and process controls, Ensco’s patented Continuous Tripping Technology (CTT) can fully automate the movement of the drill string into or out of the well at a constant controlled speed.

Ensco president and CEO, Carl Trowell calls the new technology “a step-change efficiency improvement that uses automation and innovative technology to address a repetitive, time-consuming process that is ubiquitous in offshore projects today.”

According to Trowell, “Tripping pipe is on the critical path for all drilling and workover activities and, as a result, meaningful time is spent performing this process over the life cycle of every offshore well.

“Continuous Tripping Technology significantly reduces the amount of time spent tripping pipe, and the faster tripping time that this technology offers is expected to lead to cost savings for customers regardless of water depth or well type,” he said.

Ensco claims CTT enables pipe-accelerated tripping speeds of up to 9,000 feet per hour when deployed during offshore activities. The constant tripping speed minimizes surge and swab pressure on the wellbore by eliminating intermittent stopping and starting as well as excessive peak speeds.

The system, which can be retrofitted to both floaters and jackups, and is particularly well-suited for ultra-deepwater drillships and larger modern jackups, uses automation to eliminate human error and personnel exposure associated with the conventional stand-by-stand method, according to its developer.

“Continuous Tripping Technology is another example of our ongoing investments in innovation that are focused on developing systems, processes and technologies to make the drilling process more efficient and lower offshore project costs for customers,” Trowell said.

“We continue to see better utilization for rigs that deliver the greatest efficiencies for customers’ offshore well programs and, given the proprietary nature of Continuous Tripping Technology, we expect that it will help to further differentiate Ensco’s assets from the competition and position us well for future contracting opportunities.”

Ensco said the CTT system was recently installed and is being commissioned on the 2016-built jack-up ENSCO 123. The rig is expected for delivery in March 2019 following system commissioning and rig acceptance trials.