Houston-based ProSep has won a water treatment project contract for Woodside's Scarborough gas development offshore of Western Australia

The contract, for end-client Woodside, which sanctioned the $12 billion Scarborough development in November 2021, is with an unnamed American multinational company, and, according to ProSep, has a seven-figure value.

ProSep, said that the Scarborough water treatment project would see the company deliver its water treatment technology OSORB Media Systems (OMS) which will be its first time operating in the region.

"The OMS is designed reduce contaminants including benzene, toluene, ethyl benzene, and xylene (BTEX) to less than 10 parts per million (ppm) on a floating production unit (FPU). This contract will launch ProSep into the Australian market, working in a natural gas resource which is playing a crucial role in assisting neighbouring Asian countries act on reducing emissions to meet increasing energy demand. The region has been a focus for ProSep in recent years and will remain a focus for the business moving forward as they commit to increase their footprint in the Asia-pacific area," ProSep said.

Chief Operating Officer for ProSep, Greg Hallahan, said: “The OMS technology is extremely sophisticated and provides unique environmental benefits, and removes hydrocarbons from the water using a physical adsorption process that is reversed during the regeneration process.”

The delivery time of the Osorb Media System for Scarborough is at the end of 2022.

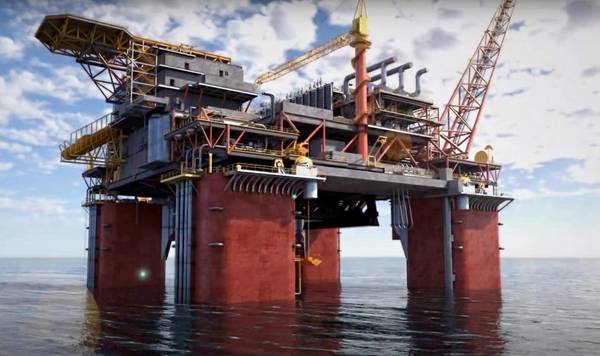

In January this year, offshore engineering and construction firm McDermott secured a contract with Woodside to deliver the hull and topsides for the floating production unit to be installed at the Scarborough development.

The FPU will process natural gas, which includes gas separation, dehydration, and compression as well as monoethylene glycol regeneration and produced-water handling.

Designed for a production capacity of up to 1.8 billion standard cubic feet per day, the topside will be connected to the semi-submersible hull and pre-commissioned prior to transportation and installation in a water depth of 3,100 feet (950 meters), approximately 248 miles (400 kilometers) offshore Western Australia. The FPU will be capable of being remotely operated and minimally staffed during normal production operations.