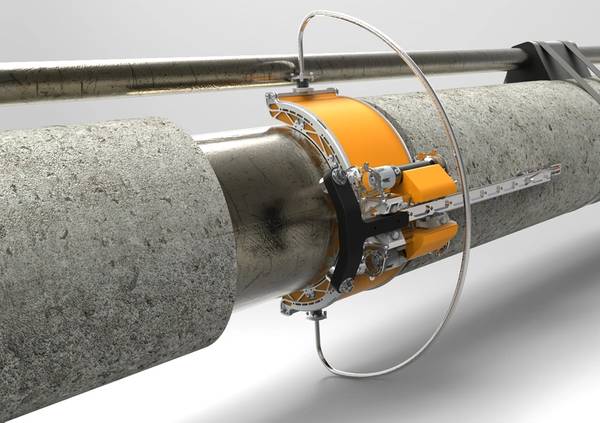

TSC Subsea has designed a new ROV-deployed automated scanning tool that addresses the issue of carrying out tight access field joint inspection through difficult to penetrate pipeline coating.

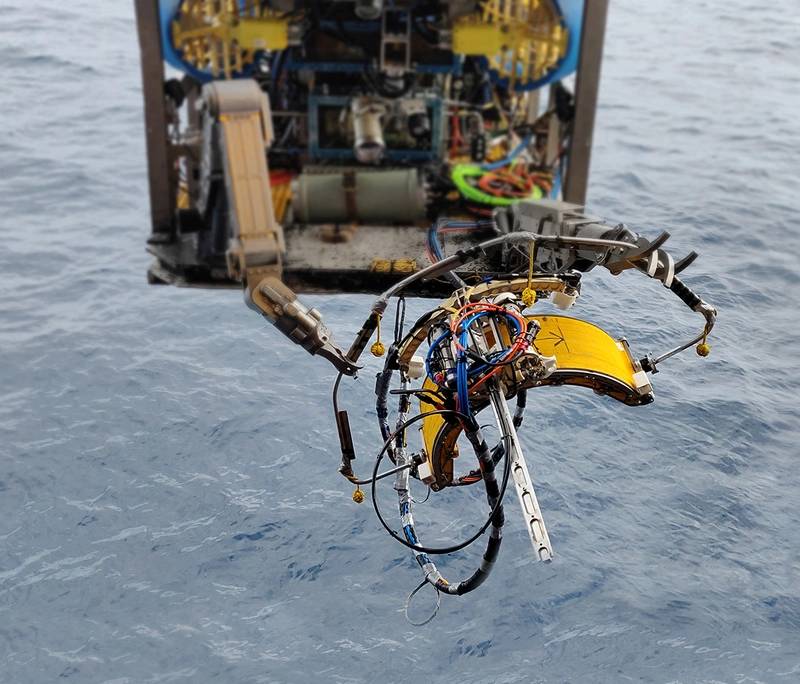

The ARTEMIS vCompact, a smaller, lightweight, more-flexible version of the standard ARTEMIS, was designed, developed and built by TSC Subsea’s engineers to work in tandem with inspection class ROV for the remote inspection of pipelines and structures. It was designed and built in a turnaround time of less than six weeks to meet the precise requirements of a project for Beach Energy in Australia’s Bass Strait, to carry out wall thickness inspection on the 20” Otway pipeline near the Thylacine A platform.

The location of the pipeline joints required the inspection to be conducted remotely within a very narrow field joint section which was too confined for the standard ARTEMIS. The solution, in the form of the ARTEMIS vCompact, was developed.

Its design incorporates TSC Subsea’s industry-leading Acoustic Resonance Technology (ART). ART is the only high-resolution technology that penetrates and inspects through thick subsea coating with lightweight, high-precision 3-axis scanning to produce high accuracy wall thickness measurements and corrosion mapping.

Strong magnetic feet fix the scanner firmly in position. The ROV then detaches and stands off, negating the need for it to hold station accurately for long periods of time. The tooling utilizes motorized and encoded manipulators which enable the probe to accurately follow the areas to be inspected. Inspection data is transferred to a topside computer and can be analyzed from anywhere in the world.

“The ARTEMIS vCompact successfully completed its operations for Beach Energy with flying colors, with all inspections being performed within two days,” said Stephan Freychet, Senior Project Manager. “All the data from the remote inspection was analyzed remotely by a team in Norway.

“This project demonstrated the potential of the ARTEMIS vCompact and the industry-leading capability of ART. It can be deployed in a number of applications where size and agility are crucial in overcoming the problems of tight access. This, combined with the capability of ART to produce high resolution data through anti-corrosion coating without having to remove that coating, means that it provides a high-specification solution to challenges such as these.

“Having proven its credentials, there is huge potential for its use in and around subsea structures and pipelines where accurate remaining wall thickness measurements are critical for safe operations.”

Jonathan Bancroft, Global Sales Manager said, “Our client had a problem with no solution, and in just six weeks our engineers designed, built and tested the ARTEMIS vCompact to address the market gap.’’

(Photo: TSC Subsea)

(Photo: TSC Subsea)