The P&A scope is large and the challenges diverse. It’s also an activity that’s increasing. In 2017, for the first time, more wells were abandoned in the UK North Sea (approximately 160) than new wells were drilled (less than 100), as fields reach the end of their productive lives. Here, some 1,400 wells are expected to be plugged and abandoned over the next 10 years. It’s a costly endeavor with no economic return.

The UK Oil & Gas Authority’s (OGA) UKCS Decommissioning 2019 Cost Estimate Report says P&A activity is estimated to account for 44% of decommissioning costs (down from 48% in 2016). It’s hoped that bill can be cut by 35%. Inroads are being made. The Cost Estimate Report says well P&A costs have benefitted from improved scoping of required work, and better execution practices, while subsea wells have benefited from cyclically low rig/vessel rates. But, costs still fluctuate and more has to be and can be done.

The Oil & Gas Technology Center (OGTC), a public-funded body tasked with technology development based in Aberdeen, is supporting various projects. Malcolm Banks, Well Construction Solution Centre Manager, at the OGTC, says, “Abandonment work is increasing in volume and the scope is quite significant. Its was one of the first areas the industry wanted us to address (when the OGTC was founded in 2016).” Key aims are moving more toward rigless abandonment technologies, reducing the scope involved and alternative barrier materials, to replace long cement plugs, which would in turn reduce scope and reliance on rigs.

“Historically, cement has been the default, but it’s not perfect,” says Banks; getting it in place over long well sections can be time consuming and challenging. “So, industry is looking at alternatives, as well as economically implementable solutions.” The goal is plugs that can be quicker and easier to place, with integrity at least as good as cement. That also means finding easier ways to place barriers. “Historically, that’s meant removing whole tubulars, completions and cutting and pulling casing, and that can take weeks,” says Banks. “So, we’re looking at how to cut or remove sections with thermal or mechanical means.

“Another challenge is understanding the condition and the integrity of the well and geology surrounding it. A lot of wells have changed hands three or four times, and information is lost. But, that information can help reduce risk and uncertainty. So, we’re looking at cheap internal surveys up front and modeling using data and data analytics to reduce risk and uncertainty.”

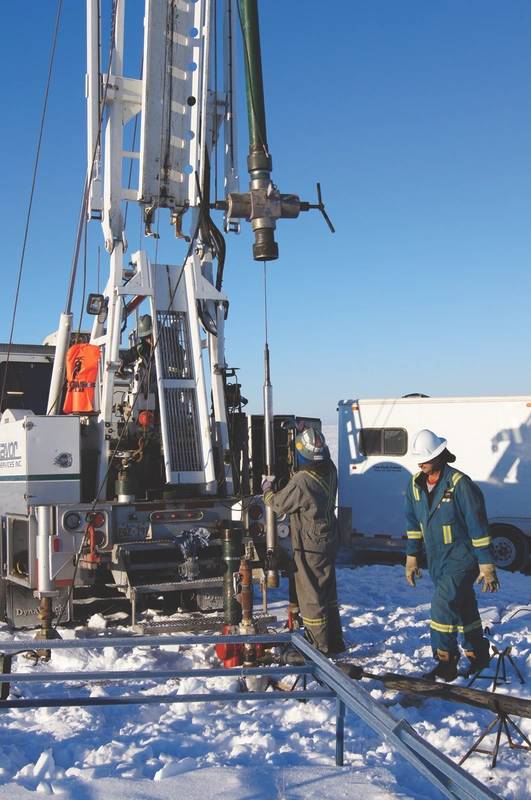

Spirit Energy has been trialing thermite plugs, onshore and offshore in the UK. (Photo: Spirit Energy)

Spirit Energy has been trialing thermite plugs, onshore and offshore in the UK. (Photo: Spirit Energy)

Fields trials

A number of projects are at field trial stage. For example, the OGTC supported two fields trials by operator Spirit Energy of thermite – a pyrotechnic composition of metal powder and metal oxide – as a way to form a barrier by burning through tubulars and casing to the formation rock. These saw Norwegian company Interwell’s thermite technology used in a well at Caythorpe, in England, in 2018, and also from the Audrey platform, in the southern North Sea, earlier this year.

The OGTC is also supporting work with BiSN, supported by BP, looking at qualifying bismuth alloy as a barrier material followed by a potential deployment. As reported in Offshore Engineer (January 2019), BiSN, based in England, is using bismuth alloy that’s melted down hole using a thermite heater. When it sets, bismuth alloy is unique in that it expands. BiSN, whose name stems from Bi for bismuth and Sn, for tin, in the periodic table, has already had a trial in Norway with Aker BP, as we reported in January. Another firm looking at use of alloys, deployed through tubing on electric wireline or slickline and used with thermite downhole as a replacement for cement, is Aberdeen-based Isol8, led by former Interwell managing director Andrew Louden. Isol8 is also working with the OGTC and looking for field trial opportunities.

Separately, Rawwater, in England, is developing expanding bismuth alloys as sealing elements. The firm’s work with bismuth (which it calls ‘molten metal manipulation’) dates back to 2000, when the material had been used in test rigs, simulating nuclear submarine cooling circuits. Following a meeting with an oil major the same year, the firm directed its attention at P&A, using an electric downhole heater developed for heavy oil extraction, from Canadian firm SealWell, and downhole telemetry to control the heating. Prof. Bob Eden, Rawwater’s managing director, says two trial plugs were eventually set in wells in Alberta in 2010 and the company has continued working on the technology ever since, running a series of research projects. The first focused on 4-inch plugs, which were deployed onshore but subsequent pressure testing was hampered by through-wall corrosion of the casing. The second targeted offshore deployment of 7-inch plugs, working with OTM and then the Industry Technology Facilitator in the UK, supported by Shell, Nexen, Equinor and ConocoPhillips, focusing on the bismuth alloy metallurgy to achieve a 3,000-year life expectancy. In 2016, the company started an Innovate UK project focusing on developing higher temperature alloys for medium to high temperature wells, working also with the Oil & Gas Innovation Center (OGIC) and Aberdeen University.

In 2010, Rawwater set a bismuth plug onshore Alberta. (Photo: Rawwater)

In 2010, Rawwater set a bismuth plug onshore Alberta. (Photo: Rawwater)

The project has recently completed, and the result is two alloys, Alloy 80 and Alloy 150, which resist creep to 80°C and 150°C respectively, and resist corrosion in sour environments. Both alloys were certified by Bureau Veritas to be fit for the 3,000-year life requirement. Rawwater has recently formed a partnership with UK-based engineering consultancy Astrimar, and is looking for partners to deploy trials, following workshop tests at the firm’s facility in Culcheth, England. Meanwhile, Rawwater continues to advance the technology to seal micro-cracks in nuclear facilities.

Some believe cement just isn’t sufficient. Prof. Brian Smart at Encompass ICOE, an Edinburgh-based health, safety and environment resource for the offshore industry, says, “We believe cement isn’t sufficient for the long-term as a plug material one recognized reason being its chemical deterioration. The other reason its reaction to ground movement – such as reservoir subsidence or its reversal as the reservoir recharges – that stresses the rigid cement, cracking it and destroying its integrity as a plug. Richard Stark, from the same organization, says, “One of the problems is that there’s very little information about plug deterioration in situ. Integrity issues have, however, occurred in every basin due to corrosion of the steel or loss of integrity of the cement. With those two materials, that’s what’s stacking up for the future.”

They have an idea for an alternative plug material: quick clay. It’s a naturally occurring clay – found in Scandinavia and North America – that, over many years, has had the halite or salt that makes it form into a clay solid washed out. Without the salt it remains thixotropic – i.e. it tends to liquify when shaken. This property would mean it would accommodate ground movement effects without cracking bentonite has similar properties, and has been tested, but because it swells (unlike quick clay), it can fracture the well, says Dr. Carl Fredrik Gyllenhammar, who is working with Encompass ICOE and runs Norwegian firm Cama GeoScience, which received research funding to test this concept at the International Research Institute of Stavanger and the University of Stavanger.

Quick clay liquifies when agitated (Photo: Encompass ICOE)

Quick clay liquifies when agitated (Photo: Encompass ICOE)

Sticking with cement

Some companies are looking to stick with cement, but to improve it. Well-Set, based in Norway, is looking at magneto rheological cement. This involves using traditional cement but controlling how it is set – its rheology – more accurately by impregnating the cement with magnetic particles then using a magnetic field to place it, says Banks. It’s similar to a process used in car suspension where a magnetic field hardens the suspension hydraulics for “sport mode”. The OGTC has supported a desktop study with Well-Set and is now moving to a Phase 2 project, supported by ConocoPhillips, involving full scale and bench testing.

Meanwhile, at the University of Strathclyde, Glasgow, nanoparticulate silicate and biogrout technologies are being looked at. “Cement, over time, will shrink, crack and degrade,” says Banks. “The ability in the annulus to retain the barrier long term is something that’s a concern to industry.” Especially as there’s no way to go back in and repair it. So, ideas from civil engineering are being looked at, including biogrout, which uses enzymes that deposit calcium carbonate in the downhole environment. “The nanoparticular silicate, meanwhile, would get into the cement or cracks where it gels and, while hasn’t got compressive strength,” says Banks, “it has pressure retaining capacity so it helps to seal areas in a well bore that might otherwise flow.”

Another cement adaptive technology is being developed by UK-based Resolute Energy Solutions, who are testing using additives in cement that expand downhole to eliminate shrinkage. They’re on the OGTC’s TechX program, to help accelerate their work.

Testing, testing, testing

A challenge for new design well barrier materials is the criteria they must meet. Cement has been used for decades and is the default, even if it’s not perfect, as some assert. If other materials are to be used, they need to be proven. One challenge is exactly what they need to be proven to do.

Another challenge is that current criteria for well barrier materials are based on cement. “If we were to apply the same scrutiny to cement that applies to new materials, cement plugs would struggle.” says Brian Willis, research and development engineer at Astrimar. “The requirements are still very much written with a cement mindset. Qualification is done against the values and strength of cement as opposed to how a plug functions as a barrier. Not enough is being done to understand how new plugs might fail and how that may affect performance in sealing a well and remaining in place. That means there are materials that have gone through recommended qualification and field trials and which are now experiencing issues and it’s hard to ascertain what’s going wrong because early qualification testing was not as extensive as may actually be required.”

Astrimar has developed a STEM-flow predictive analysis tool to help assess the predicted life of barrier materials and P&A designs. It’s been created based on a database of materials, including cement, built by Astrimar following extensive data gathering. It was used as part of Rawwater’s product development. “With the addition of extensive TRL4 testing, the predicted life of the bismuth alloy compared with cap rock was improved greatly,” says Willis. But, he stresses, it’s not just about the material that’s deployed, it’s also about the interfaces between the material and what it’s sealing against. “In reality, the industry hasn’t fully quantified what the true risks are yet.” He says, “The regulator will have to come to grips with this, probably driven by from pressure from society as a whole.” There are also sticky questions about what level of leakage would be acceptable, given that there is natural leakage from the seabed unrelated to any oilfield activity already.

Rawwater has been focusing on extensive workshop testing at its facility in England. (Photo: Rawwater)

Rawwater has been focusing on extensive workshop testing at its facility in England. (Photo: Rawwater)

A new (test) rig

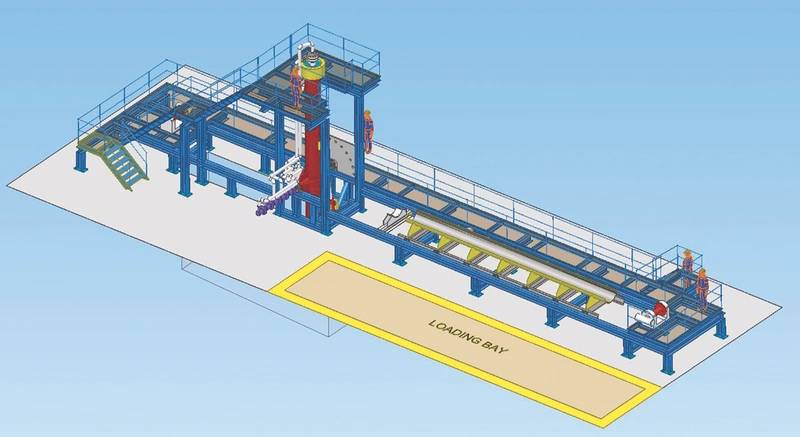

The recently created National Decommissioning Center (NDC), part-funded by The Oil & Gas Technology Center with the University of Aberdeen, is looking at building a test chamber at their Newburgh based center near Aberdeen that could put barrier materials to the test.

With funding from the Scottish Government’s Decommissioning Challenge Fund, the NDC tasked Aberdeen-based engineering firm Apollo Offshore Engineering to design a rig in which barrier materials could be tested to 150 °C and 10,000 psi, covering 80% of UK continental shelf (UKCS) wells. The 20-inch internal diameter test chamber will be able to house cartridges that can simulate the different annuli in a well, with different tubing and casing (up to 18¾-inch diameter) arrangements, in a repeatable way. It is also designed to simulate inflow from the well or rock and flow return through the annulus. It would even have a slickline equipment interface to mimic real downhole conditions.

Dr. Richard Neilson, who’s been working on the project, says it would be a pretty unique test facility, designed with industry input, including from the OGTC’s Alternative Barrier Material Collaboration Group, which includes developers and operators.

“There are a number of barrier technologies being developed, like the use of thermite and thermite combined with bismuth alloy, and also resin and well scaling,” says Dr. Neilson. “Once it’s down in a well, there are things you can do to test it, such as putting instrumentation down, like pressure transducers above and below. But at some point you want to see what’s happening. We can set a plug and test it under pressure and then examine it; the morphology of what’s been generated. There’s a big advantage to being able to do that. You can show that these materials will do what was expected in downhole conditions.”

The examination of the materials can go even further at the university, using computed tomography (CT) scanners it’s invested in over recent years, which means the porosity of the material can be seen. The next challenge is funding to make it a reality. With that in place, Dr. Neilson says it could be built in about 18 months.

The National Decommissioning Center’s P&A materials test rig design. (Image: NDC)

The National Decommissioning Center’s P&A materials test rig design. (Image: NDC)

Getting mechanical

In the well placement arena, the OGTC supported initial work with Oilfield Innovations, an Aberdeen based startup that’s looking at ways to cut and compact tubulars, so that rock to rock sections can be opened without removing the material from the well. In 2017, the firm ran trials of the concept and, last year, it worked with the University of Strathclyde to better understand some of the processes.

The OGTC is also working with Aberdeen-based SPEX at a system development stage – pre-bench testing – to use controlled explosives to crumble targeted sections which would then fall down the well. The OGTC is also supporting another Aberdeen firm, Deep Casing Tools, to develop its Casing Cement Breaker tool – a kind of eccentric roller that’s run downhole to deform the casing and break up the cement. The technology was run offshore, in a trial with Equinor, earlier this year. The OGTC project’s goal is to make it a one-trip tool, able to cut, break down the cement, and then latch, in one trip.

And there’s more. The OGTC’s TechX technology accelerator program also has Sentinel Subsea on its books – a firm developing a hydrocarbon sniffing technology which would detect any traces of a pre-placed substance that have leaked from beneath the well barrier. On detection, a signal would be sent to shore, noting where the leak came from in the well.

There is plenty going on, plenty more to do and many questions to be answered. Luckily, there are many people trying and much more to come.

(Image: Interwell)

(Image: Interwell)

| Interwell continues testing |

|---|

Interwell’s goal is to deploy thermite P&A technology on wireline, hugely reducing rig requirements. Since 2016, the firm has run trials in 18 different wells: 15 onshore Canada and one in Italy, as well as the two in the UK. The most recent trials were last winter/spring in Canada, with three different operators in nine wells. “The main focus was surface casing vent flow/sustained casing pressure fix, as an alternative to today’s methods,” says Christian Rosnes, Commercial Manager – P&A, Interwell. “So far, there are some very promising results. One well has been cut and capped while the remaining eight will be evaluated this autumn. “We are fortunate to have a full-scale test rig, which allows us to build a wellbore to test the system in. We are then able to section cut the well bore and barrier to investigate the complete cross section, as well as to see the actual result. This gives us useful knowledge about how we can improve the robustness of the system. Field trials and full-scale testing combined with comprehensive CFD modeling enables us to understand and control the physical aspects of our barrier. Going forward we are working on adapting the system with the new information we gained in the field and also at our test facilities. “Our main focus areas, aside from CFD- and phase modelling, laboratory and HP testing are looking at geochemistry/geology, chemistry, well elements, thermo science and mechanical design. In the coming months we are preparing for more trials with several operators.” |